Part of something bigger

Proud Part of the German Schunk Group

As part of the Schunk Group, AIXEMTEC combines entrepreneurial agility with the strength of a global technology leader. Our customers benefit from enhanced innovation power, financial stability, and access to a global service and support network. Being part of a strong international group means long-term reliability, global reach, and scalable solutions – without losing the flexibility and customer focus that define AIXEMTEC.

What we do

Engineering Precision at scale

From prototype to mass production, we deliver machines that meet the exact demands of the photonics industry.

Applications

Highlight applications

Discover how our machines power the next generation of

photonic devices.

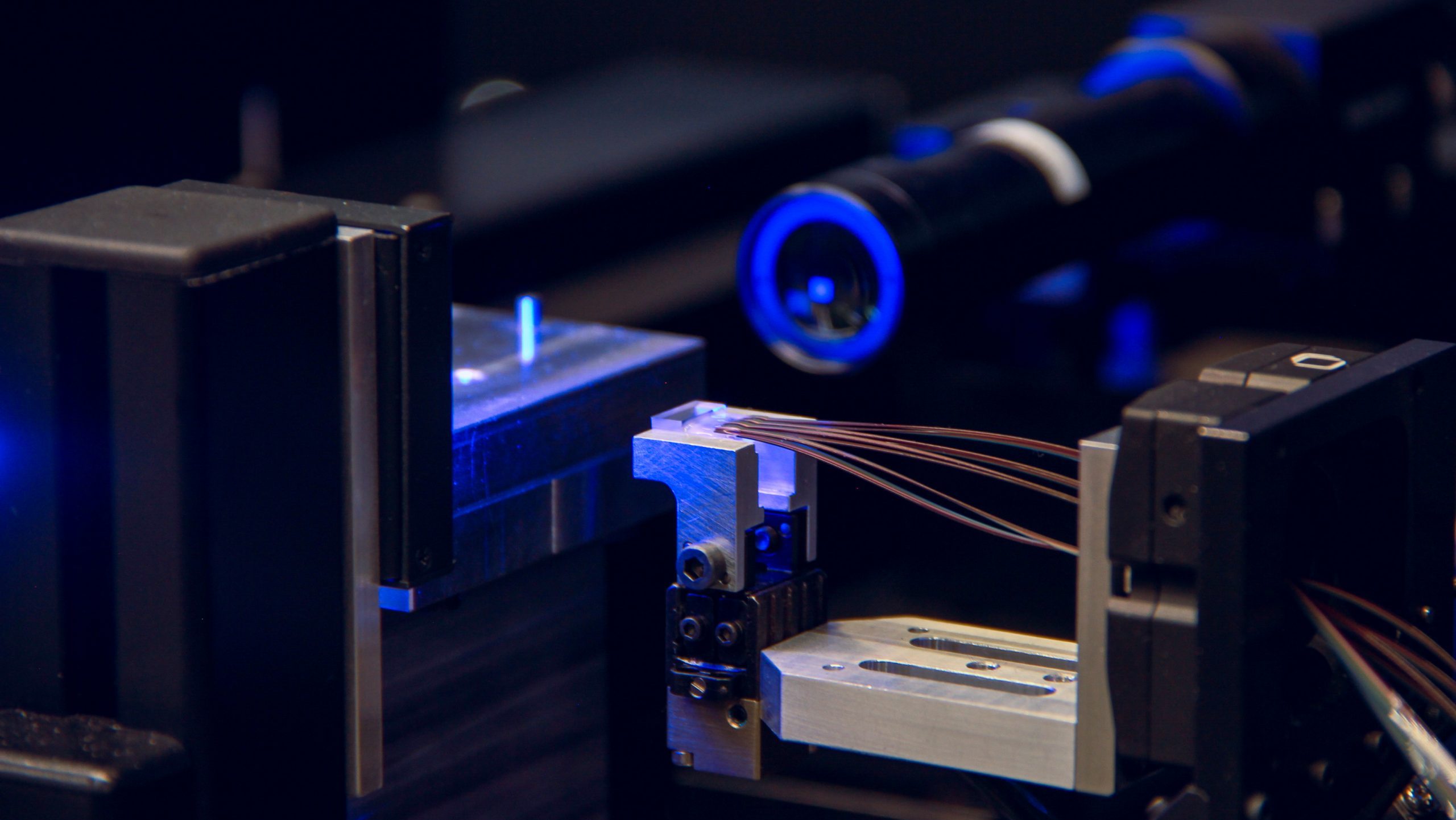

Camera Assembly

AIXEMTEC enables function-optimized camera assembly with active alignment, precision bonding and scalable automation – first-time-right from prototype to mass production. Learn more…

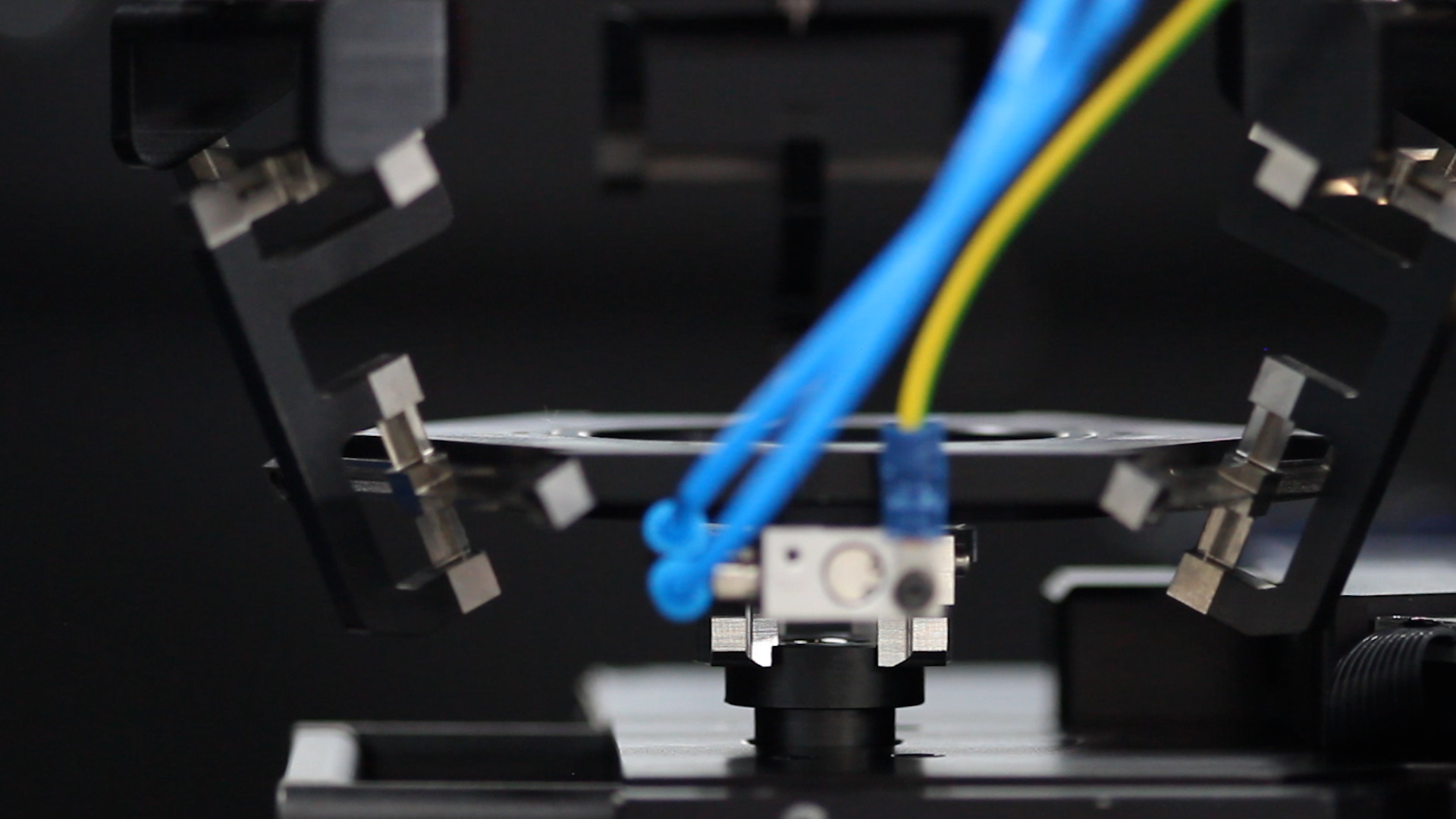

Optical Transceiver Assembly

AIXEMTEC enables function-controlled optical transceiver assembly with fiber expertise, active alignment and scalable automation – bridging the gap between photonic R&D and industrial mass manufacturing. Learn more…

Why AIXEMTEC

Your Benefits

We engineer competitive advantages into

every machine we build.